Lasers and floors, sophisticated combination

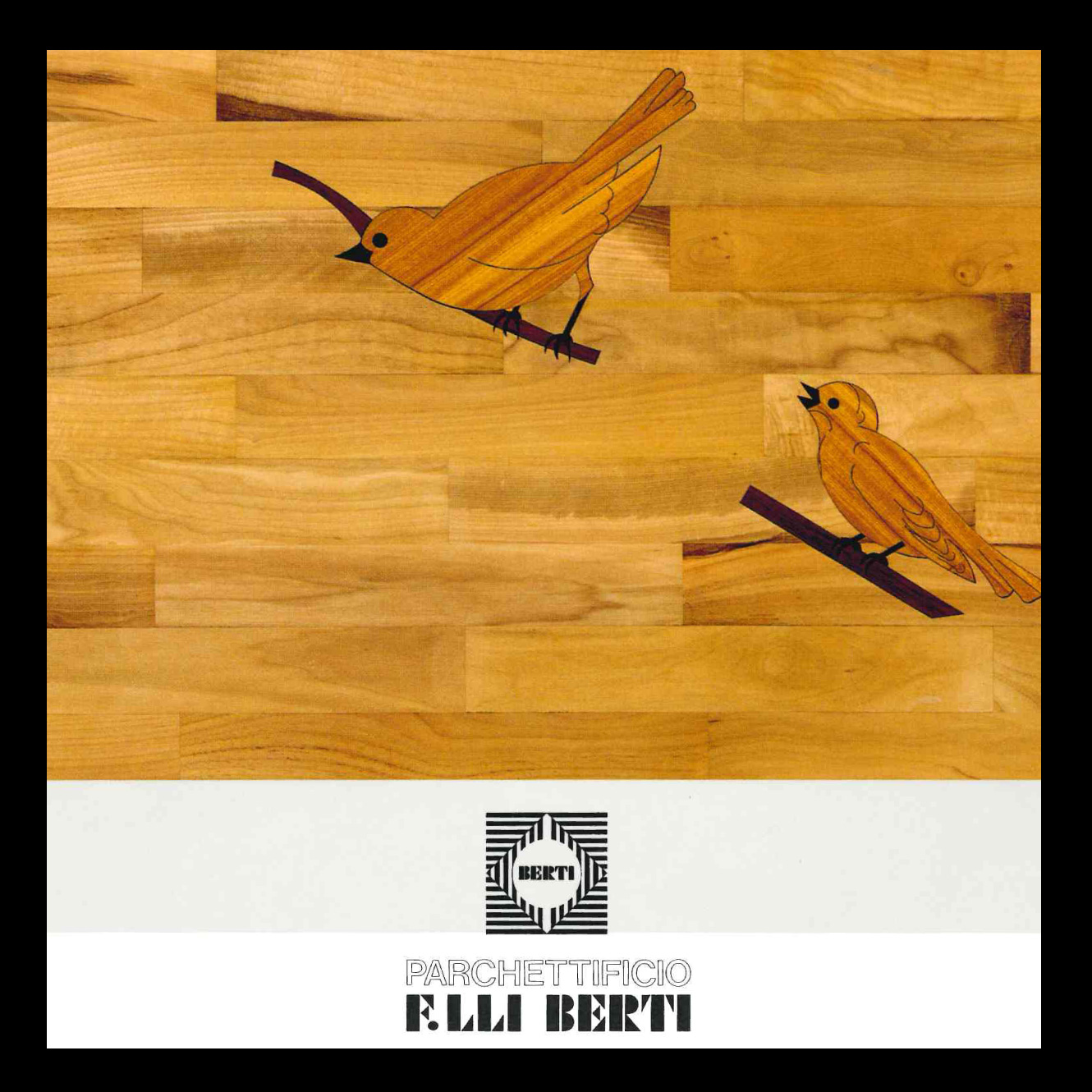

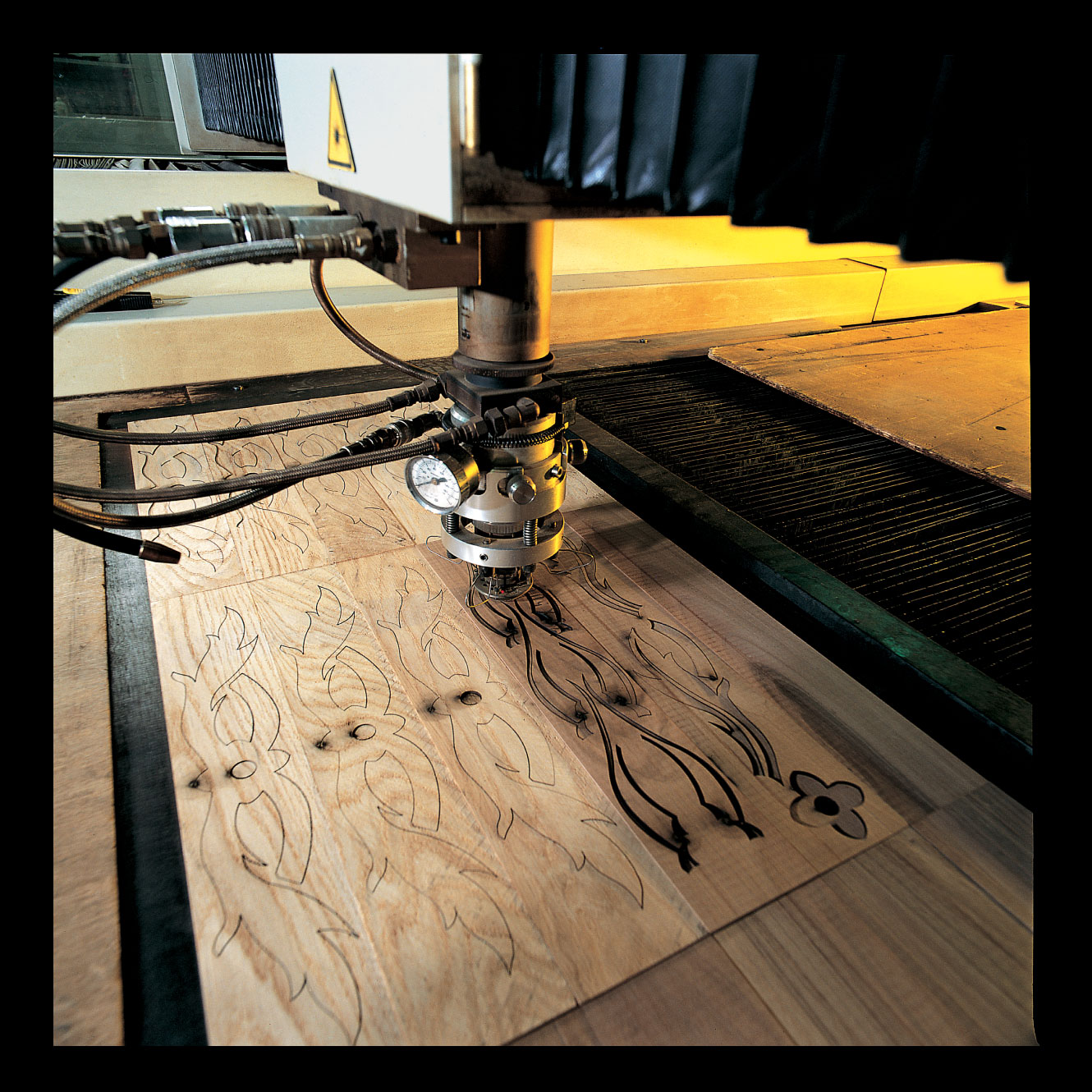

The company was the first in the world to study the application of laser technology to make fine parquet and inlaid floors, true works of art that have made Berti Pavimenti Legno an unparalleled benchmark in terms of this advanced processing technique and the demand for luxury parquet. Thanks to the contribution of this technology, simple wooden planks of solid or prefinished wood are transformed into elegant decorations. Tiny pieces of essence, tastefully juxtaposed and joined together, can create true masterpieces.

Get a quote,

enter the Berti world

Fill out the form to request a quote.

You will receive a reply from our Staff in a short time.

Uncompromising quality: parquet made in Italy, enhanced by Berti’s exclusive processing techniques

A noble layer

Berti pays special attention to the preparation of the noble wood and the substrate, favoring the technical qualities of birch wood to ensure maximum stability. By carefully observing the bonding time, the possibility of the first layer detaching from the second is eliminated.

Hi-Tech Painting

Strictly Italian

Berti has developed an innovative parquet finishing technique using water-based varnish applied by roller, thus ensuring a floor that is resistant to stains and wear. This HI-tech coating, carefully executed on an industrial UV-drying plant, offers exceptional hardness and a natural textural effect, while ensuring precise control of the drying and curing process. Antibacterial parquet with BERTI SILVER PROTECTOR a special finish that uses the powerful action of silver ions to protect your environments by eliminating 99% of bacteria in just 24 hours. The ideal solution for environments with high sanitizing needs: medical offices, beauty salons, restaurants or, for healthier rooms in the home such as bathrooms, kitchens or children’s rooms.

All the certified naturalness of quality parquet flooring

CE Certificate

Berti products bear the CE marking. It guarantees their compliance with the essential requirements, stipulated in the sector directives, for safety, public health and consumer protection.

VOC

VOC or VOC (Volatile Organic Compounds) certification defines the volatile compounds in a product according to its impact on the air you breathe contained in the environment.

FSC®

Request FSC®-certified wood flooring. Forest Steward Council® certification attests that the raw material comes from forests that are managed properly, transparently and controlled according to FSC® standards.

CARB

CARB certification, although mandatory only in California, has been assumed as the U.S. gold standard influencing many European manufacturers of semi-finished or finished products to control formaldehyde emissions.

Dolomiti Energia

The “100% clean energy Dolomiti Energia” label identifies the origin of electricity from a renewable source and represents a new concept of energy consumption.

Man and environment. Building and furnishing the space of the former while respecting the life and integrity of the latter. It is in the very nature of Berti products to care for the health of those who live, walk, and work on its floors, as well as to contribute to the energy balance of the environments in which they are placed.